ABOUT US

Neuland is a company manufacturing and marketing of metal products for nearly 20 years.

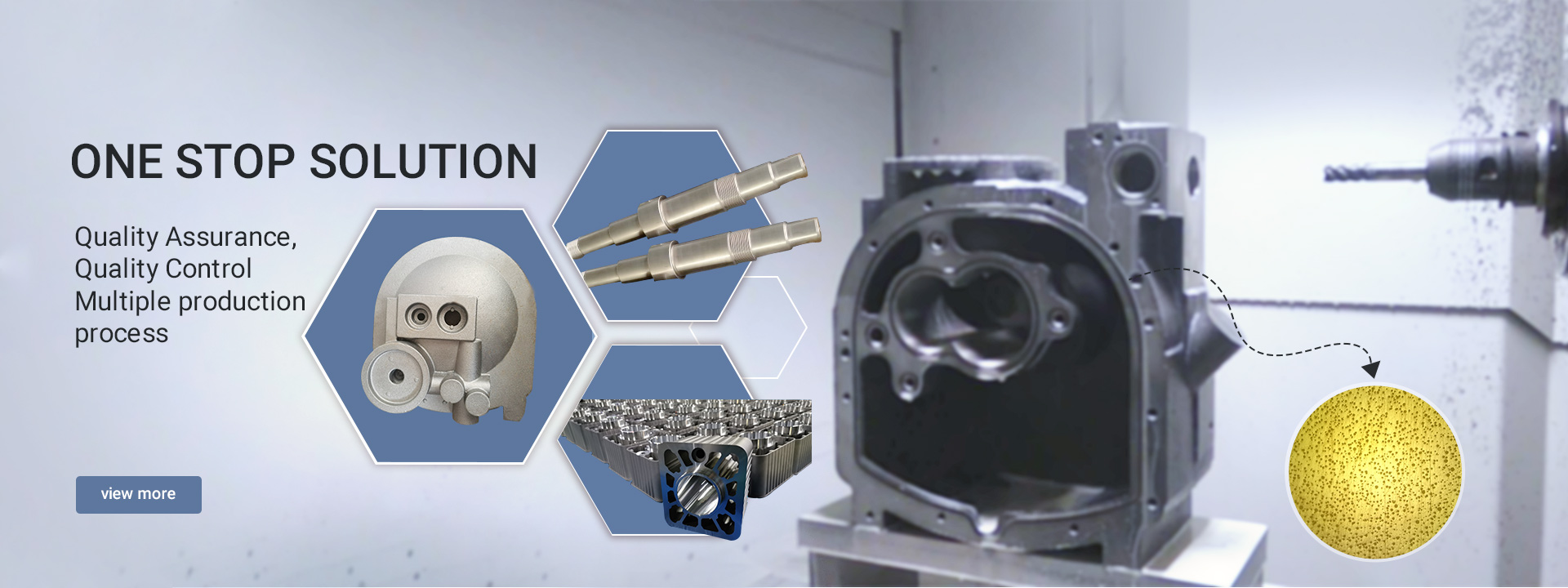

The company has been supplying products in materials cast iron, steel, stainless steel, aluminum, copper etc by production methods sand casting, die casting, lost wax casting and die forging and precision machining. Assembling and surface coating service are also available.

And over the past years, the company has grown up as a whole process solution provider for any metal products in various industries. Either your drawings can be shaped into products, or even your idea can be realized into a satisfactory product starting designing to shipping. Moreover, our engineering team is capable and more than happy to provide our proposals to you on valuable change of production method and material to best fulfill the cost reduction and function of a product.

NEWS

-

Typical Application Cases of SS Forging

V. Typical Application Cases Forging Type Material Process Highlights Technical Breakthrough Source Nuclear Power Support Ring Austenitic Stainless Steel Metal Constructive Technology: Small slabs vacuum packaged → High-temperature forging bonding → R... -

Core Technical Elements of S S Welding

III. Main Forging Process Routes 1. Hot Forging (Mainstream) The vast majority of stainless steel forgings are produced via hot forging. Heating Temperature: Depends on grade. Austenitic: 1150-1250°C; Ferritic: lower. Key Steps: Heating: Step heating or controlled ... -

Stainless Steel Forging

Stainless steel forging is fundamentally different from carbon steel forging. The core challenges lie in the narrow forging temperature window, high deformation resistance, and strict microstructure control. The following provides a complete technical framework covering materi... -

aluminum welding

III. Pre-Weld Preparation: 70% of Success Aluminum welding abhors “dirt” and “delay.” Thorough Cleaning (Three-Step Method) : Degreasing: Wipe off oil, grease, and fingerprints using acetone or isopropyl alcohol. Film Removal: Scrub unidirect... -

Technical Introduction to Aluminum Welding

The core challenges of aluminum welding boil down to three “enemies”: Oxide Film (Al₂O₃), High Thermal Conductivity, and Hydrogen Porosity. Welding aluminum is not an “upgraded version” of welding steel—it is a completely different discipline. From clea...

LATEST PRODUCT

Get the latest news delivered daily!

Give us your email and you will be daily updated with the latest events, in detail!