Investment casting workshop

The investment casting plant is well accredited with ISO9001:2008 and PED ADW-0 certificates. The products are produced in stainless steel,carbon steel,copper and aluminum serving wide industries like flow control, automotive, chemical, food, pharmacy, energy and lot more general industries, etc. The part weight can be from 0.1kg to 50 kg.

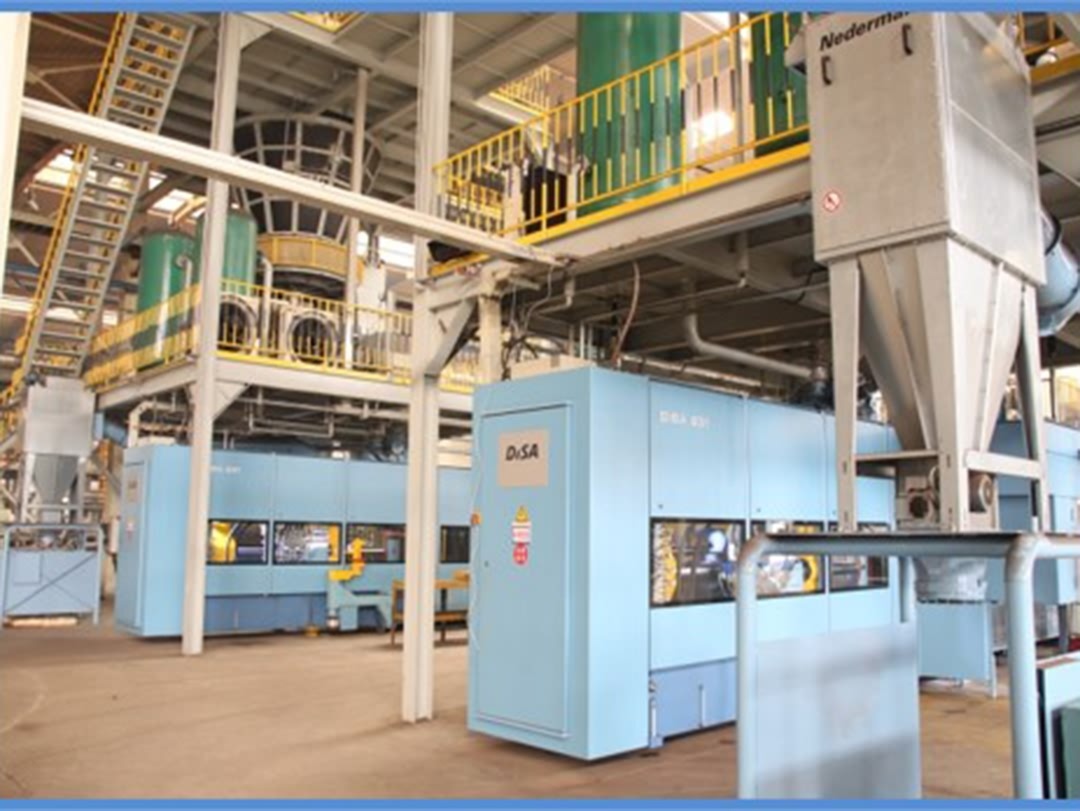

Sand casting workshop

Our sand casting shops are producing castings in material cast steel, ductile iron, grey iron, aluminum, brass etc. The production facilities are Disamatic, horizontal lines, water glass sand,hot shell core molding, resin sand molding. The casting weight can be from 0.1kg – 500 kg.

The products with our sand castings plants are widely used in industries like automotive, machinery, water, gas, oil, energy, fire protection, utility and lot more general industries.

Die casting workshop

The die casting workshop includes high pressure die machine 6 sets and low pressure die machine 4 sets. Currently, we are producing parts for wind power generation, auto parts, Chemical machinery, Medical equipment and so on. The main material applicable is various aluminum and zinc such as:

A356/A319/A413/A380/A390/A360/ADC10/ADC12/ ZL101/ZL102/ZL104/ZL107/LM6/LM/20/LM25/EN AC-42100/EN AC-42200/EN AC-43000/EN AC-43200/EN AC-43300/EN AC-43400/EN AC-44200/EN AC-44300/EN AC-46000/ENAC-46100/ENAC-46200/ENAC-46500/ENAC-47100/zinc

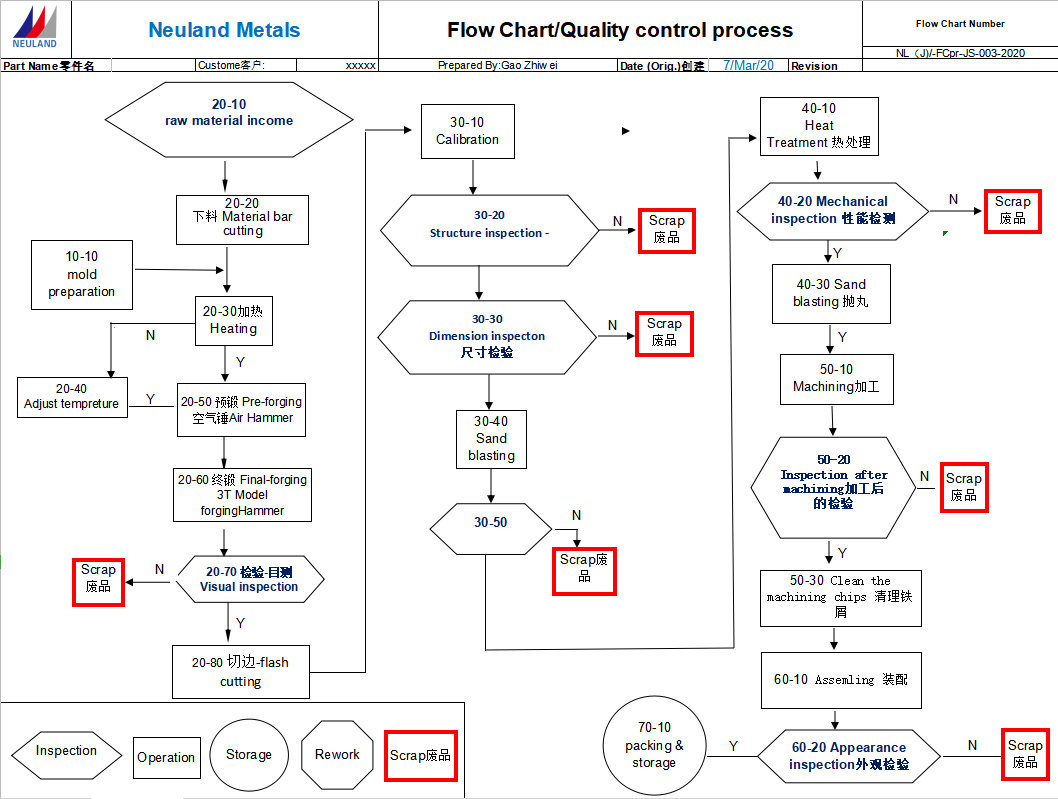

Forging workshop

The forging plant is consisting of both free forging and die forging facilities. The maximum single part weight is 100kg. The forging parts are serving a good variety of industries such as train, trenching, commercial vehicles, heavy duty vehicles, constructions, etc. The materials that are available with us are steels with different grades, stainless steel and brass.

After forging, we are also capable of providing all required heat treatment services.

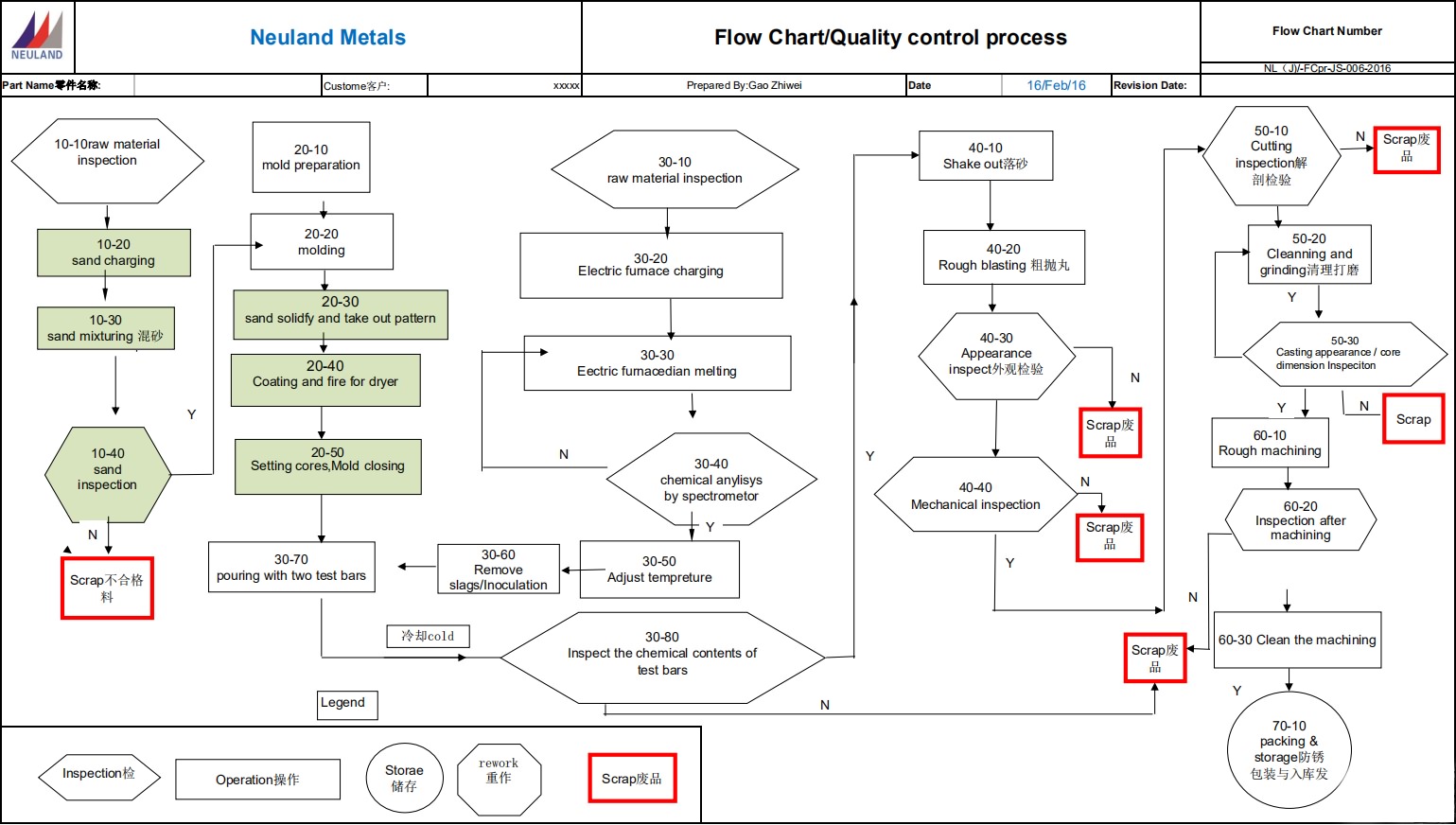

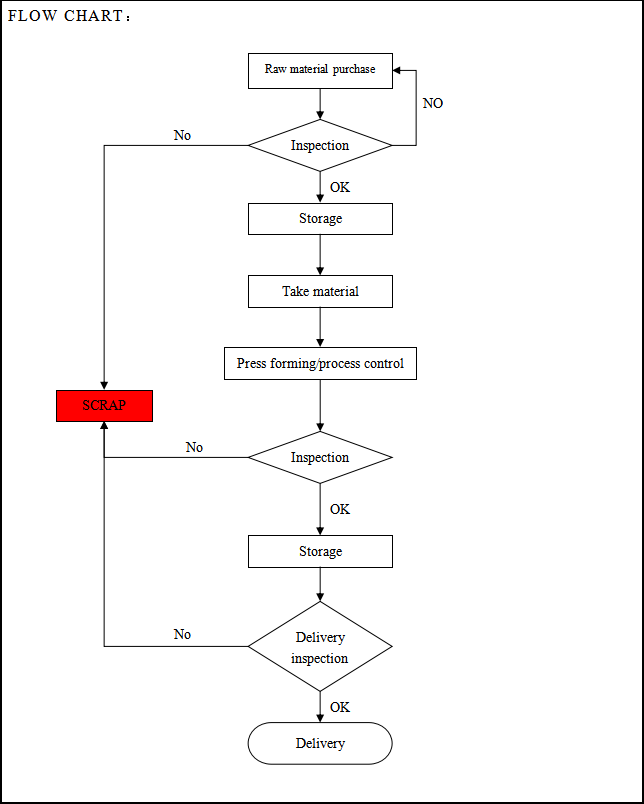

Flow chart- Rough:

CNC machining workshop

Our precision machining shop mainly produces customized cnc machining parts, normally produce according to customer design with in house and sub-contracted equipment. The parts size range are between 5mm - 2000mm with the max tolerance +/-0.02mm. Currently we mainly produce housings, covers, shafts, gears with material in aluminum, stainless steel, cast iron and steel, copper and zinc.

Here are our main machining facilities:

Mazak Vertical machining center: 6 sets with plate 1050x980mm

Makino Horizontally machining center: 10 sets with max plate 1100mm x 600mm

CNC milling machine: 6 sets with max plate 1900 x 800mm

CNC lathe: 14 sets with max size 850 x 650mm

Drilling, cutting, boring, grinding.... machine: 8 set

Fabrication workshop

Manufacturing process flow chart:

Laser cutting, Plasma cutting, Water cutting, stamping, bending, Arc welding, Co2 shield arc welding are the most popularly used methods with our fabrication products. The trenching, digging, energy, water, flow control are the 5 industries that our products are serving.

Surface coating workshop

The surface coating services we can provide include E-plating, E-painting, powder coating, galvanizing, Enameling and Electroless Nickel coating according to customer requirements. The coating materials include paint, Nickel, Chrome, epoxy resin powder, rilsan, zinc, enamel.