News

-

The difference between cast aluminum and die-cast aluminum

Cast aluminum generally refers to aluminum castings made by casting technology, while die-cast aluminum refers to aluminum castings made by high-pressure die casting. The difference between the two is mainly the casting process. Casting processes generally include sand casting, lost wax casting, ...Read more -

WEDM-LS

Low Speed Wire Cut, also called WEDM-LS, uses continuously moving thin metal wires (called electrode wires, usually copper wires) as electrodes to perform pulse spark discharge on the workpiece, generating a high temperature of more than 6000 degrees, which can erode metal and cut. A CNC machinin...Read more -

Stainless Steel Automotive Parts

Investment casting technology can ensure the accuracy of part shape and size and produce high-quality parts. The use of stainless steel materials can provide parts with good corrosion resistance and strength, making them suitable for use in the automotive industry. There are many types of car par...Read more -

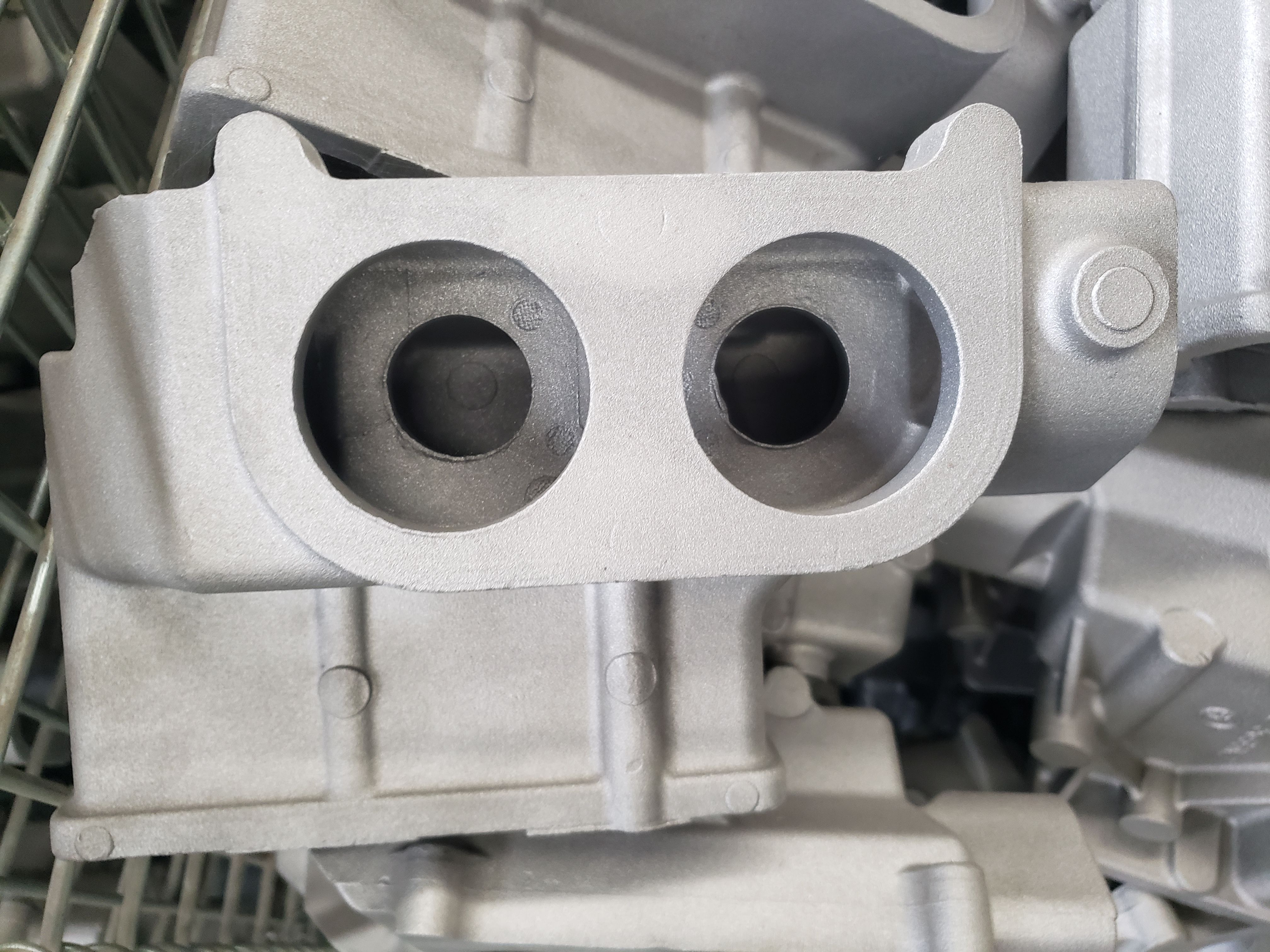

Metal parts’ housing

The box body is the core part of the construction machinery transmission system. The main processing content is the plane and the hole system. The processing quality of the workpiece determines the assembly accuracy and working performance of the machine. The following introduces the processing s...Read more -

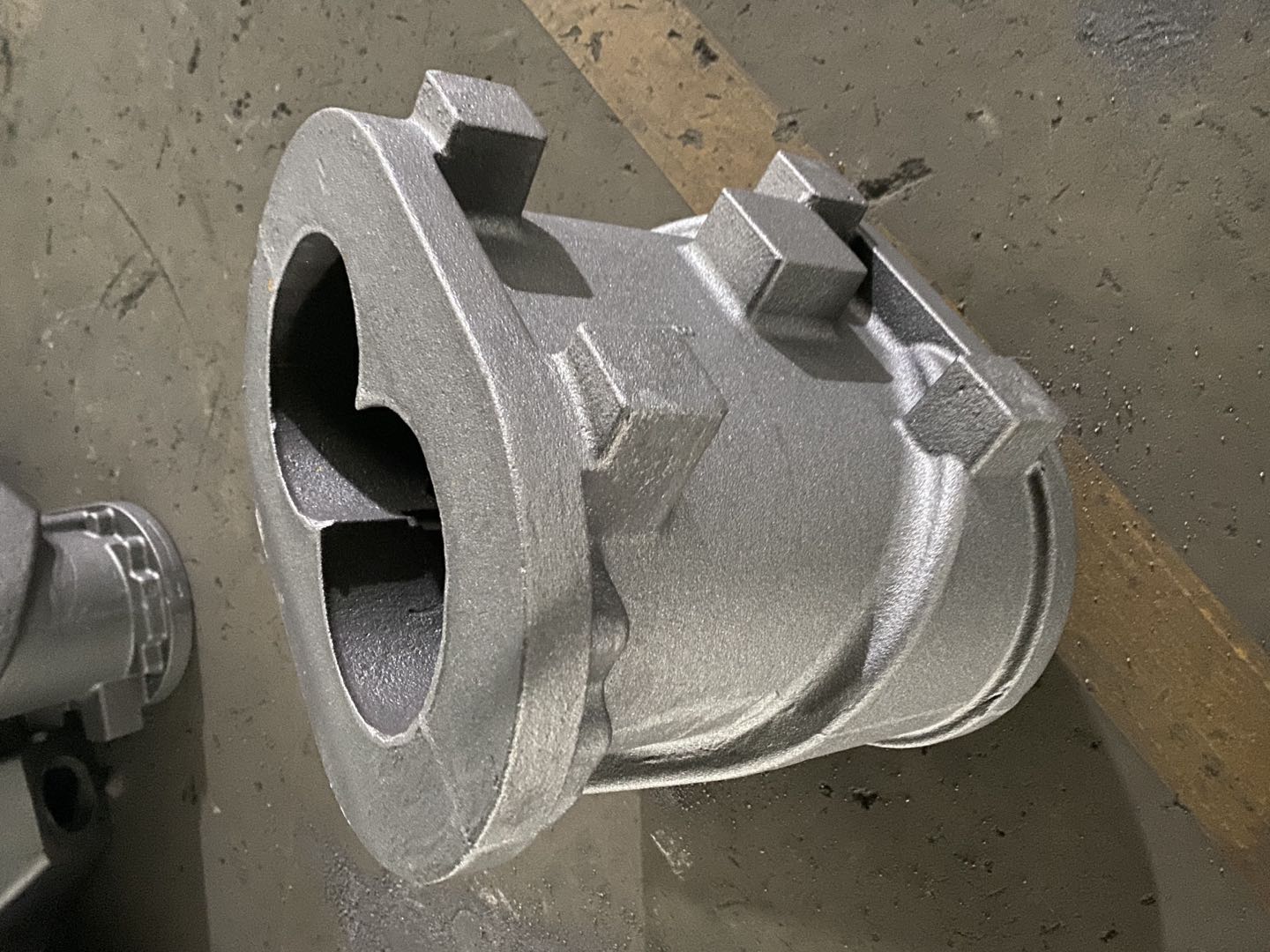

Custom Cast Iron Couplings

Couplings are also called shaft couplings. A mechanical component used to firmly couple the driving shaft and the driven shaft in different mechanisms to rotate together and transmit motion and torque. Sometimes it is also used to connect shafts and other parts (such as gears, pulleys, etc.). It ...Read more -

Custom metal parts for hydraulic pile rig

Custom metal parts for hydraulic pile drivers can vary according to specific needs, here are some common custom metal parts: Piling Hammer: The piling hammer is the core component of the hydraulic pile driver and is generally made of high-strength alloy steel. According to different work requirem...Read more -

Heat Treatment Development

Technical level: China’s heat treatment technology has improved significantly in recent years. Chinese heat treatment enterprises have not only introduced advanced heat treatment equipment, but also actively carried out technical exchanges and cooperation at home and abroad, and mastered a ...Read more -

Flat grinding machining

Flat grinding machining is a process used to smooth out the surface of a workpiece by using an abrasive grinding wheel. This process is commonly used in manufacturing and metalworking industries to achieve precise flatness and parallelism on metal or non-metal surfaces.During flat grinding machin...Read more -

Surface Treatment-Sand Blasting

Sand blasting is a process for surface treatment of workpieces. Compressed air is used as the power to form a high-speed jet beam to spray the spray material (copper ore, quartz sand, corundum, iron sand, sea sand) onto the surface of the workpiece to be treated at high speed, so that the appeara...Read more -

What parts are suitable for forging?

What parts are suitable for forging 1. Shaft parts Shaft parts are suitable for production by forging process. The forged shaft can obtain excellent strength and toughness. Compared with other manufacturing processes, it has higher precision and surface quality, so it is widely used in the produc...Read more -

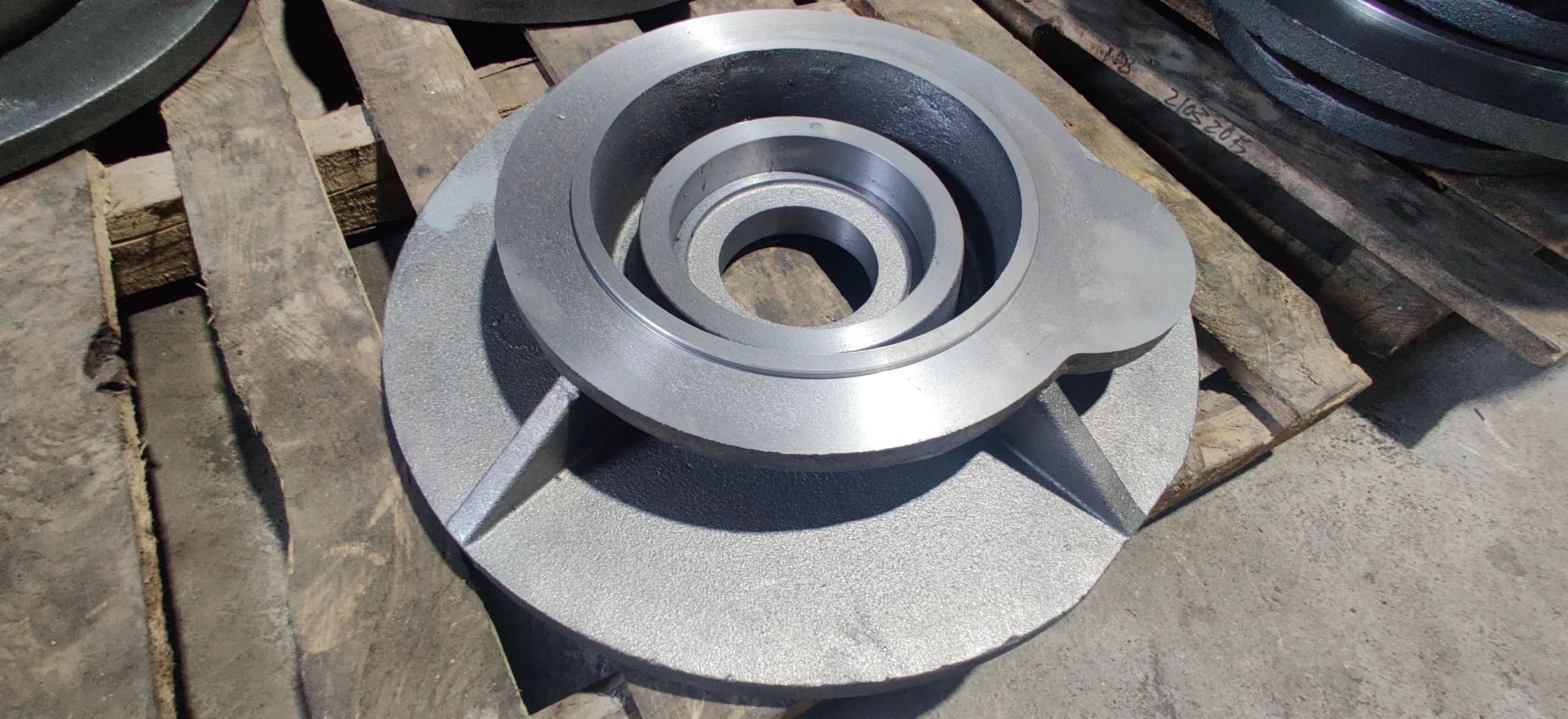

Gray Iron Castings

Gray cast iron refers to cast iron with flake graphite, because the fracture is dark gray when broken, so it is called gray cast iron. The main components are iron, carbon, silicon, manganese, sulfur, and phosphorus. It is the most widely used cast iron, and its output accounts for more than 80% ...Read more -

Should low carbon steel be tempered after carburizing?

1. Carburizing is to place the workpiece made of low-carbon steel or low-carbon alloy steel in a carbon-rich active medium. The commonly used heating temperature is 850~950°C, and keep it warm for several hours, so that the carburizing medium is produced on the surface of the workpiece. Activated...Read more