News

-

what is Stamping

Stamping is a forming processing method that applies external force to plates, strips, pipes and profiles by presses and molds to cause plastic deformation or separation to obtain workpieces (stamping parts) of required shape and size. Stamping and forging belong to plastic processing (or pressur...Read more -

Correct use of heat-resistant steel castings

In order to improve the service life of heat-resistant steel products, water glass casting products, reduce the production cost of the manufacturer, and increase the service life of the products, this brief introduction is prepared for users’ reference according to our experience in heat-re...Read more -

What is Precision casting

#Precision casting is a casting method relative to the traditional casting process. It can obtain relatively accurate shape and high casting precision. The more common practice is: first design and manufacture a mold according to the product requirements (with very little or no margin), cast wax ...Read more -

Lost Wax Investment Casting Small Metal Parts

OEM stainless steel casting with silica sol process is more advanced than the traditional process, the product quality is high, and the processing demand is small. Stainless steel casting silica sol investment casting for water pump impeller valve body is a casting method in which the shape and s...Read more -

Die Casting Parts

Die-casting is a kind of pressure-casting parts. It is a pressure-casting mechanical die-casting machine equipped with a casting mold. The metal such as copper, zinc, aluminum or aluminum alloy heated to a liquid state is poured into the feeding port of the die-casting machine. Die casting, casti...Read more -

What is Heat treatment

Heat treatment refers to a metal thermal processing process in which the material is in a solid state by means of heating, heat preservation and cooling to obtain the expected structure and properties. In the process from the Stone Age to the Bronze Age and Iron Age, the role of heat treatment is...Read more -

Precision casting

Precision casting can also be divided into gravity casting and pressure casting according to the pouring process of molten metal. Gravity casting refers to the process of pouring molten metal into a mold under the action of the earth’s gravity, also known as casting. Gravity casting include...Read more -

Water glass precision casting

The process of sodium silicate shell has been produced for nearly 50 years in China. Through the unremitting efforts of colleagues in the investment casting industry for half a century, the application and research of sodium silicate shell process have reached a very high level. Over the years, t...Read more -

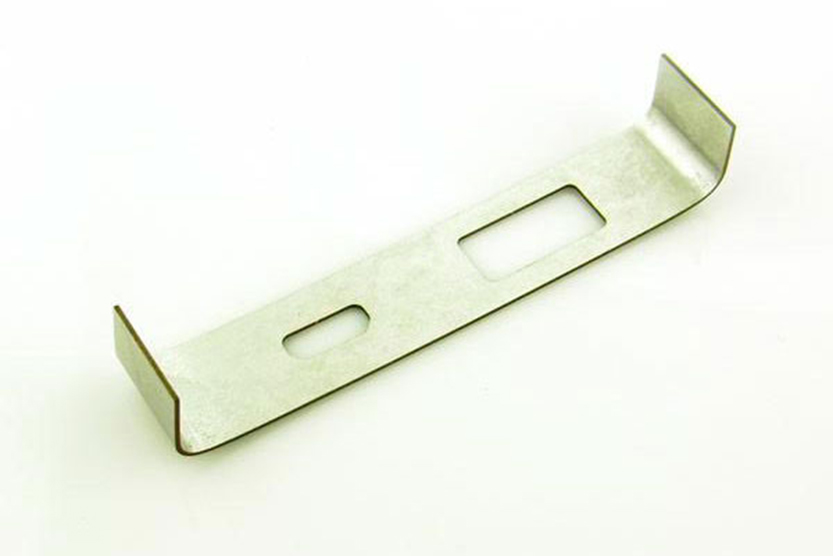

Bending Process

Bending is a stamping process that uses pressure to force a material to plastically deform to form a shape with a certain angle and curvature. Bending is one of the most common sheet metal fabrication operations. Also known as press bending, flanging, die bending, folding and trimming, this metho...Read more -

The stamping process can be divided into two categories?

Stamping and forming The stamping process can be divided into two categories: separation process and forming process. Separation process: The separation process refers to the process of separating the blank along a certain contour line to obtain a stamping part of a certain shape, size and cross-...Read more -

What is the difference between sheet metal processing and stamping processing?

First of all, conceptually, sheet metal processing refers to the processing of metal sheets, which is to use sheets to make common items in our daily life, such as chimneys, iron barrels, oil tanks, ventilation ducts, elbows, and rounded places. , funnel-shaped, etc., it is mainly made by cutting...Read more -

Powder Coating Process

Powder coating is the use of electrostatic spraying machine to spray powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the workpiece to form a powder coating. At present, there are four main types: arc s...Read more