News

-

Different types of welding characteristics and processing methods

There are more than 40 kinds of metal welding methods, mainly divided into three categories: fusion welding, pressure welding and brazing. fusion #welding Fusion welding is a method in which the workpiece interface is heated to a molten state during the welding process, and the welding is complet...Read more -

Details of cooling operations in the investment casting process

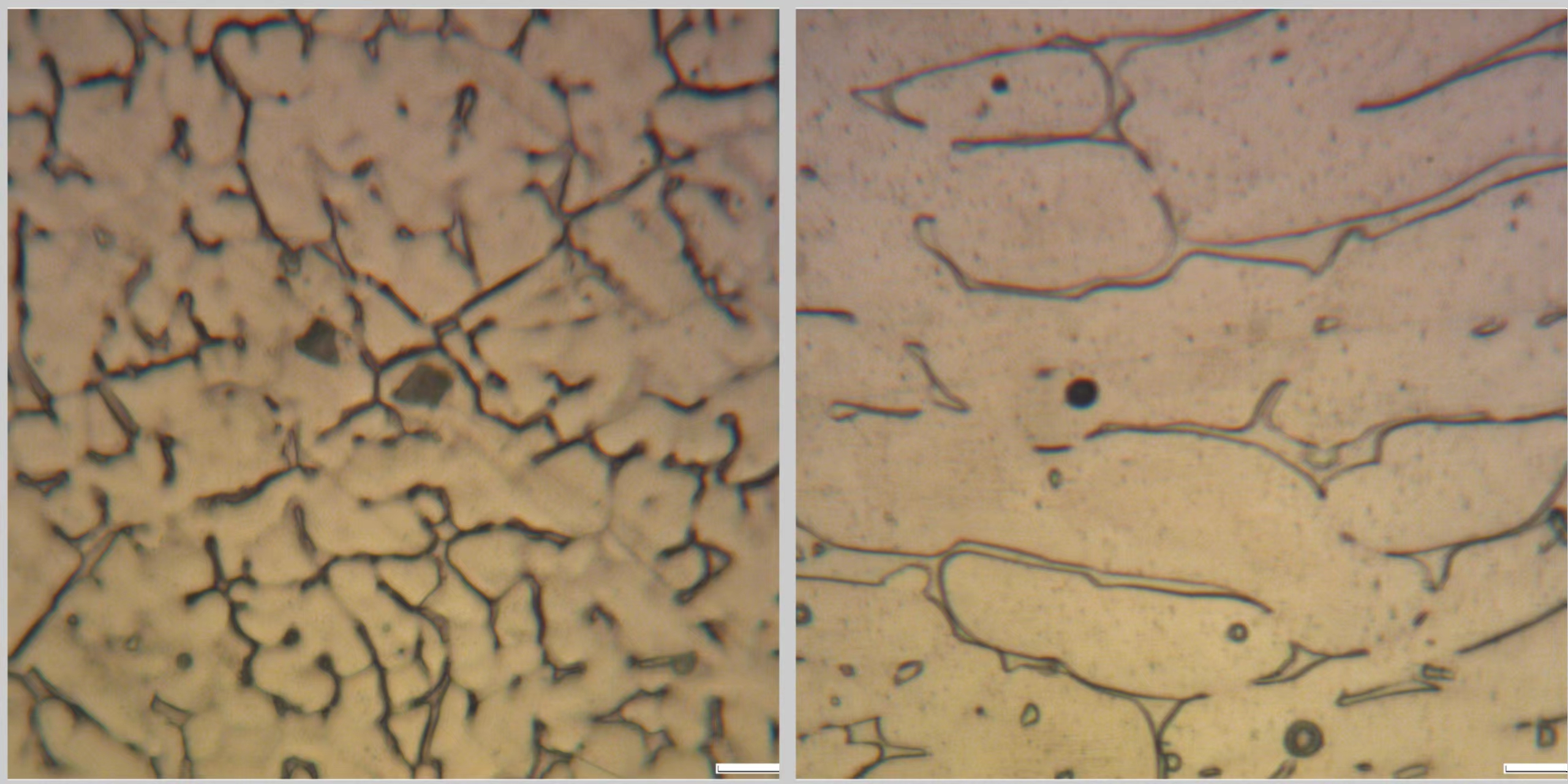

The application range of precision castings is getting wider and wider, and there are more and more processing techniques. Among them, the cooling process is an essential process, and some also undergo the solid phase transformation of the alloy. During this process, the contrast of metals change...Read more -

Solution treatment of 304 stainless steel castings

Solid solution treatment refers to the process of heating the alloy to the temperature at which the second phase can be completely or maximally dissolved into the solid solution, and then keeping it for a period of time, cooling it faster than the second phase precipitates from the solid solution...Read more -

The working principle of horizontal machining center

The spindle of a horizontal machining center is horizontal, usually with a square table for indexing rotary motion. Generally, there are 3 to 5 motion coordinates. The common one is three linear motion coordinates plus one rotary motion coordinate. It can make the workpiece complete the processin...Read more -

Salient Features of Horizontal Machining Centers

The horizontal machining center is widely used in the processing of box parts, shell parts, disc parts, and special parts in the automotive, mold, machinery manufacturing and other industries. The parts can automatically complete four-sided milling, boring, Drilling, expanding, reaming, tapping a...Read more -

How are the parts manufactured?

Machining (machining) simply means that the material is processed by mechanical equipment, such as cutting the material by cutting, so as to process the desired workpiece shape. According to the drawings and dimensions of the drawings, the whole process of making the shape, size, relative positio...Read more -

Lathes are classified by use and function

Lathes are divided into various types according to their purpose and function: The ordinary lathe has a wide range of processing objects, and the adjustment range of the spindle speed and feed is large, and it can process the inner and outer surfaces, end faces and internal and external threads ...Read more -

Features of stamping process

Stamping parts are mainly formed by stamping metal or non-metal sheet materials with the help of the pressure of the press through the stamping die. It mainly has the following characteristics: ⑴ Stamping parts are made by stamping under the premise of low material consumption. The parts are ligh...Read more -

The difference between strong spin and normal spin

Spinning can be divided into ordinary spinning and strong spinning according to the deformation characteristics of metals. Although they are a kind of processing technology at the same time, but there are certain differences in the technique and the effect of processing. The following provides t...Read more -

What is casting production

Casting production is a complex thermoforming process, and the production of a casting is limited in many ways. Usually, a suitable production method is determined according to the structural complexity, quantity, precision requirements, material, size, processing, surface treatment requirements,...Read more -

Electric Discharge Machining

The method of dimensional processing of materials by using the corrosion phenomenon produced by spark discharge is called EDM. CNC EDM is a computer digitally controlled EDM, which realizes multi-axis linkage machining. CNC EDM realizes automatic control through computer to complete complex and ...Read more -

Introduction to Gravity Casting

Permanent mold #casting refers to a process in which molten metal is injected into a mold under the action of the earth’s gravity, also known as gravity casting. The generalized gravity #casting includes sand casting, metal casting, investment casting, lost foam #casting, mud casting, etc.;...Read more