News

-

Application of shell molding and resin sand molding

Shell molding . Sand or core sand with a layer of solid resin film on the surface of the sand before molding. There are two coating processes: cold method and hot method: the cold method dissolves the resin, and urotropine is added during the sand mixing process, so that the two are coated on the...Read more -

The difference between high pressure casting and low pressure casting

The difference between high pressure casting and low pressure casting. 1. The essence of high-pressure casting (referred to as die-casting) is to make liquid or semi-liquid metal fill the cavity of the #die-casting mold (die-casting mold) at a high speed under the action of high pressure, and for...Read more -

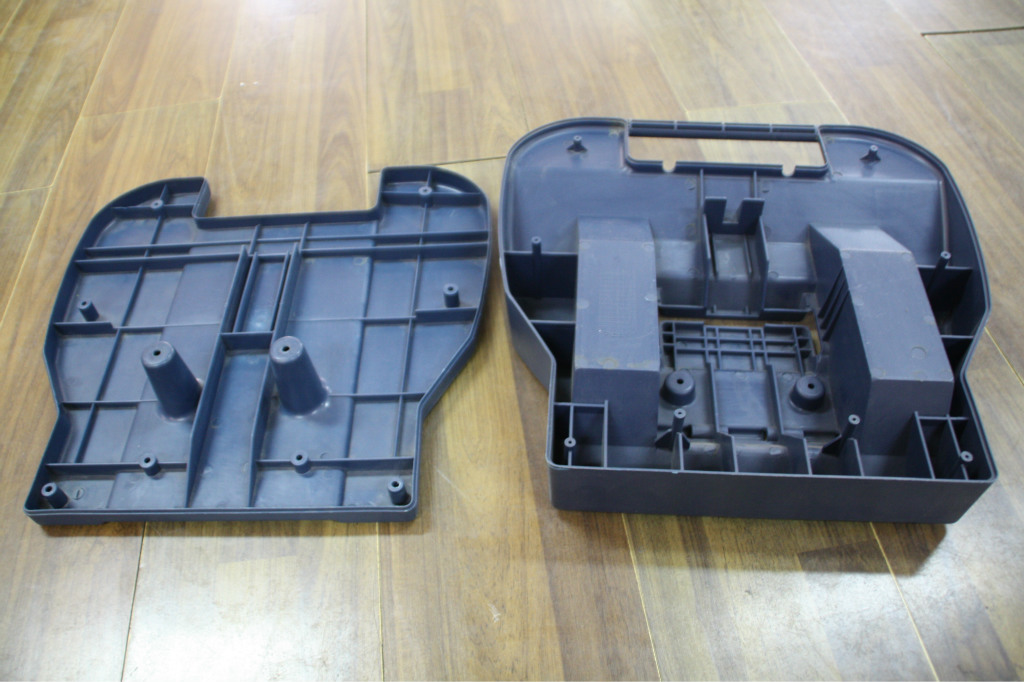

Plastic injection moulding

Plastic injection mould are mainly in the production of thermoplastic plastic products has been widely applied in the kind of forming dies, plastic injection mold and the corresponding equipment is plastic injection molding machine, plastic in the first place in the bottom of the injection machin...Read more -

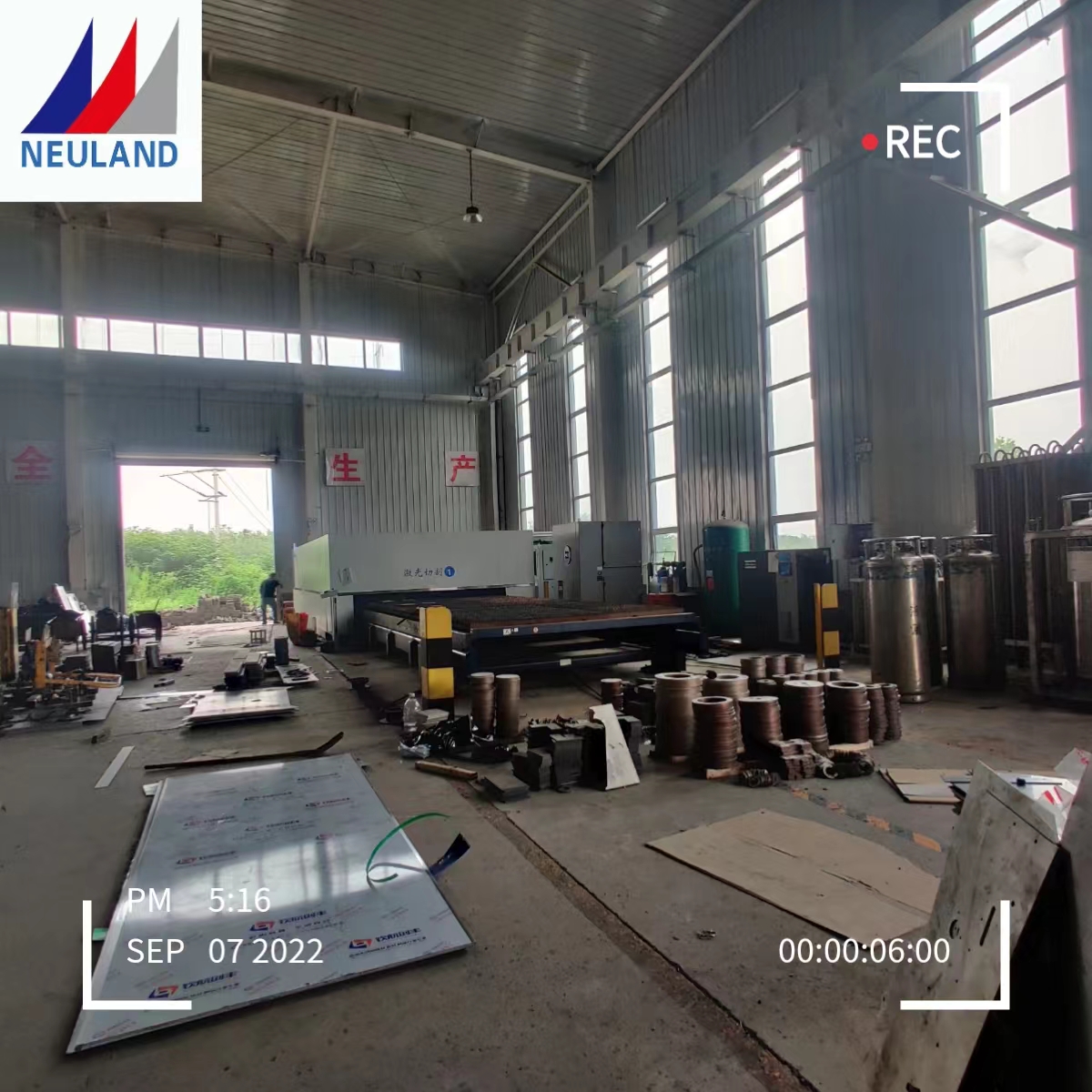

Laser Cutting

Laser cutting uses a high power density laser beam to irradiate the material to be cut, so that the material is quickly heated to the vaporization temperature and evaporated to form holes. As the beam moves to the material, the holes continuously form a narrow width (such as about 0.1mm). Cut the...Read more -

Classification of casting

There are mainly two types of sand casting and special casting. 1 Ordinary sand casting, which uses sand as a mold material, also known as sand #casting and sand casting, includes three types of wet sand, dry sand and chemically hardened sand, but not all sands can be used for casting. The advant...Read more -

Welding process and application

Welding is a process and connection method that produces atomic bonding between two workpieces of the same sex or opposite sex by heating, pressurizing, or using both. Welding has a wide range of applications, both for metals and for non-metals. Welding technology is mainly used on metal base mat...Read more -

What is cold drawn steel?

Cold-drawn steel uses hot-rolled steel as raw material, and the product quality is better than that of hot-rolled steel. For example, the cold-drawn profile causes metal work hardening due to cold deformation, which increases the tensile strength and yield strength of the cold-drawn material, and...Read more -

Ultrasonic Testing Technology-Neuland

Ultrasonic flaw detection is an advanced method of inspecting parts for defects. It mainly uses the characteristics of ultrasonic energy penetrating into the depths of metal materials, and judges whether there is a defect through the reflection that occurs at the edge of the interface when...Read more -

Gray iron properties and applications

(1) Mechanical properties The structure of gray cast iron is equivalent to taking steel as the matrix and adding flake graphite. The matrix contains more elements such as silicon and manganese than steel. These elements can dissolve into ferrite to strengthen the matrix, so the strength and hardn...Read more -

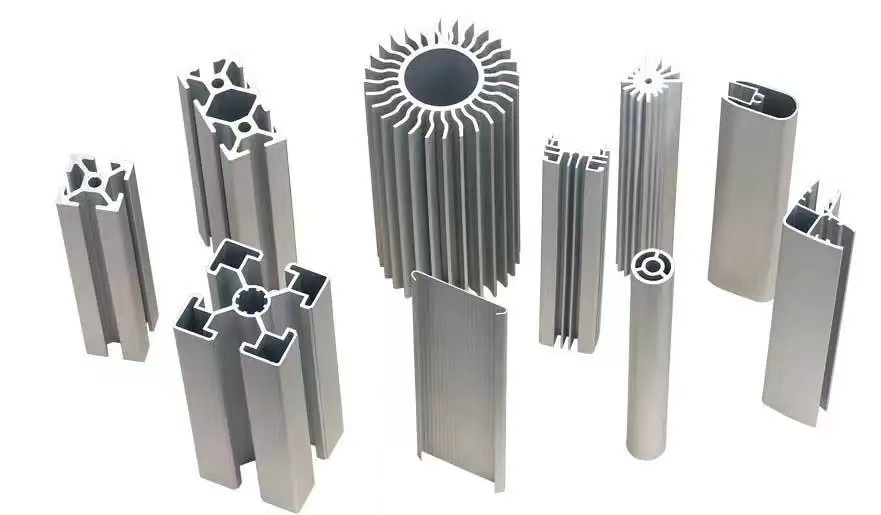

What is Profile Extrusion?

Principle of extrusion of aluminum profiles :Aluminum extrusion is a plastic processing method that applies external force to a metal blank placed in a container (extrusion cylinder) to make it flow out from a specific die hole to obtain the desired cross-sectional shape and size. Second, the co...Read more -

Heat Treatment

Heat treatment refers to a metal thermal processing process in which the material is in a solid state by means of heating, heat preservation and cooling to obtain the expected structure and properties. In the process from the Stone Age to the Bronze Age and Iron Age, the role of heat treatment is...Read more -

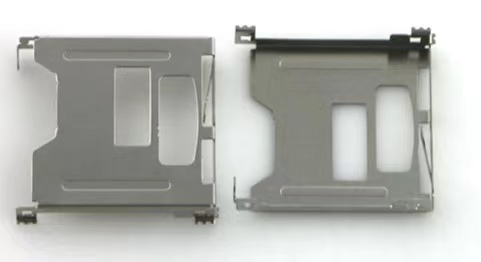

What is Stamping?

Stamping is a forming and processing method that applies external forces to plates, strips, pipes and profiles by means of presses and dies to produce plastic deformation or separation, so as to obtain the workpiece (stamping part) with the required shape and size. Stamping and forging belong to ...Read more